As the pace to develop larger and more complex distribution centres picks up it is worthwhile considering the application of simulation models to stress test your concept design and as an outcome re-risk the project. The days of 2D layouts designed from first principles are increasingly numbered due to the operational complexity that designs must now accommodate. This is why leading facility designers are increasingly turning to simulation models to develop and enhance designs.

When considering simulation it initially can be quite daunting if you have not previously used a simulation package. Consequently, a necessary first step is to think how you plan to use simulation as in reality not all packages are equal or applicable to the task. For instance, if the task calls for building and analysing detailed processes, a package that incorporates a process builder such as ExtendSim would be a good go to choice. Whereas when designing a distribution facility the capability contained with a package such as Körber’s warehouse3D design simulator software allows for the evaluation of new layout configuration, process interfaces, door counts, shift and MHE resource patterns often portrayed over a weekly cycle.

Like all modelling successful simulation is based on knowing what scenario you wish to test and taking the time to develop the required inputs needed to support the test. Some examples within a Distribution Centre environment could be testing operational scenarios relating to picking strategies, shift patterns or MHE resource models. From a structural perspective confirming door counts or the sizing of staging areas can be scenarios to test. A good simulation package run by a proficient user can quickly set up the necessary workflows to support the test and generate results.

Beyond testing the design, a hidden additional benefit of the 3D model and real-time playback is that it can serve as a powerful internal sales tool. A video playback of the 3D model operation can be a powerful tool used to support the approval of business case. In particular where the decision-making executive may not be familiar with the subject matter.

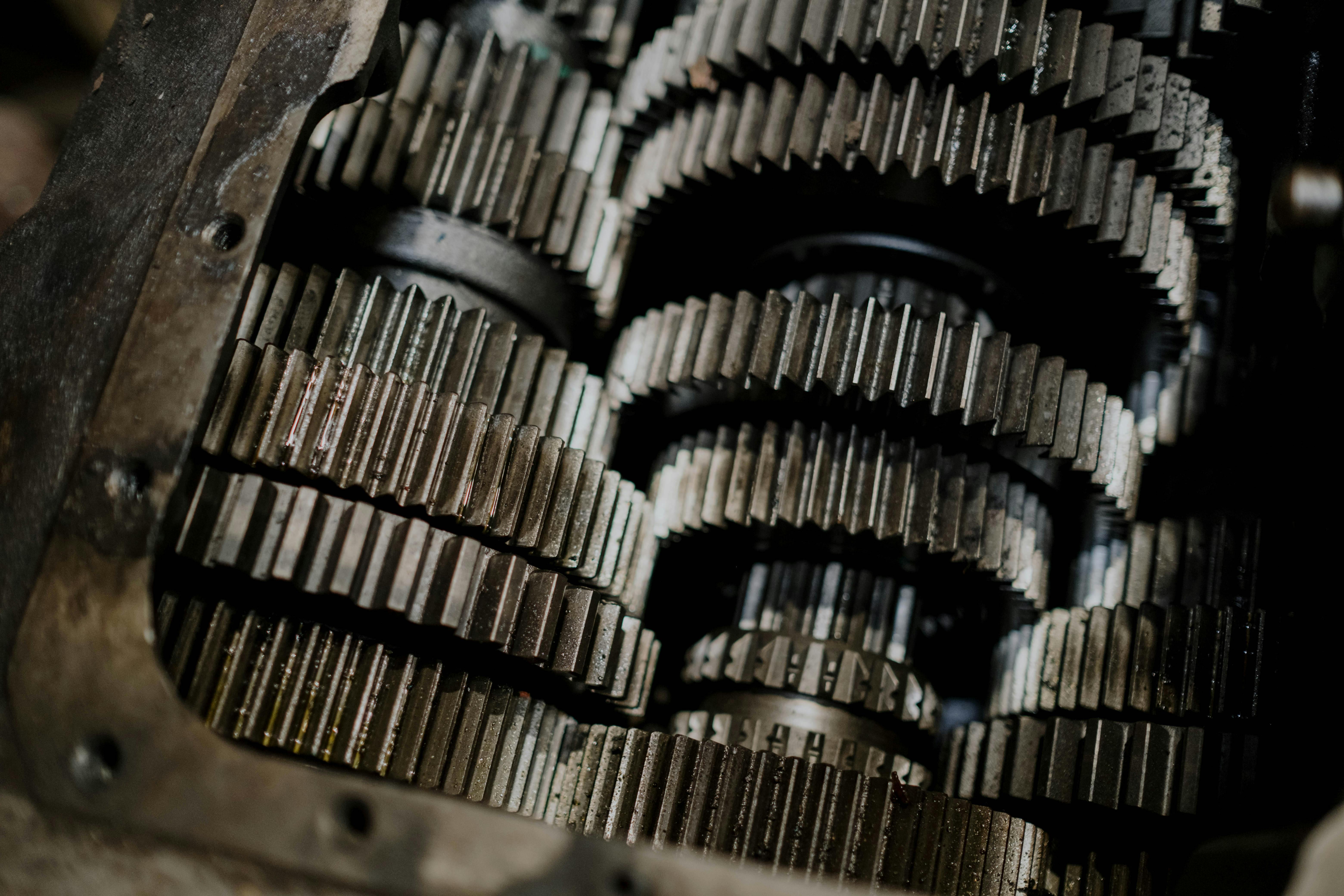

A wider use of simulation can be its use to optimise legacy facilities and extend their useful life, develop the optimal design of manufacturing lines, maintenance workshop flows and indeed model traffic flows through development precincts.

Having conducted a number of simulation engagements covering port precinct, facility design and manufacturing plant design the Siecap team is equipped to support you on the simulation journey. Contact our team at siecap.com.au to learn more.