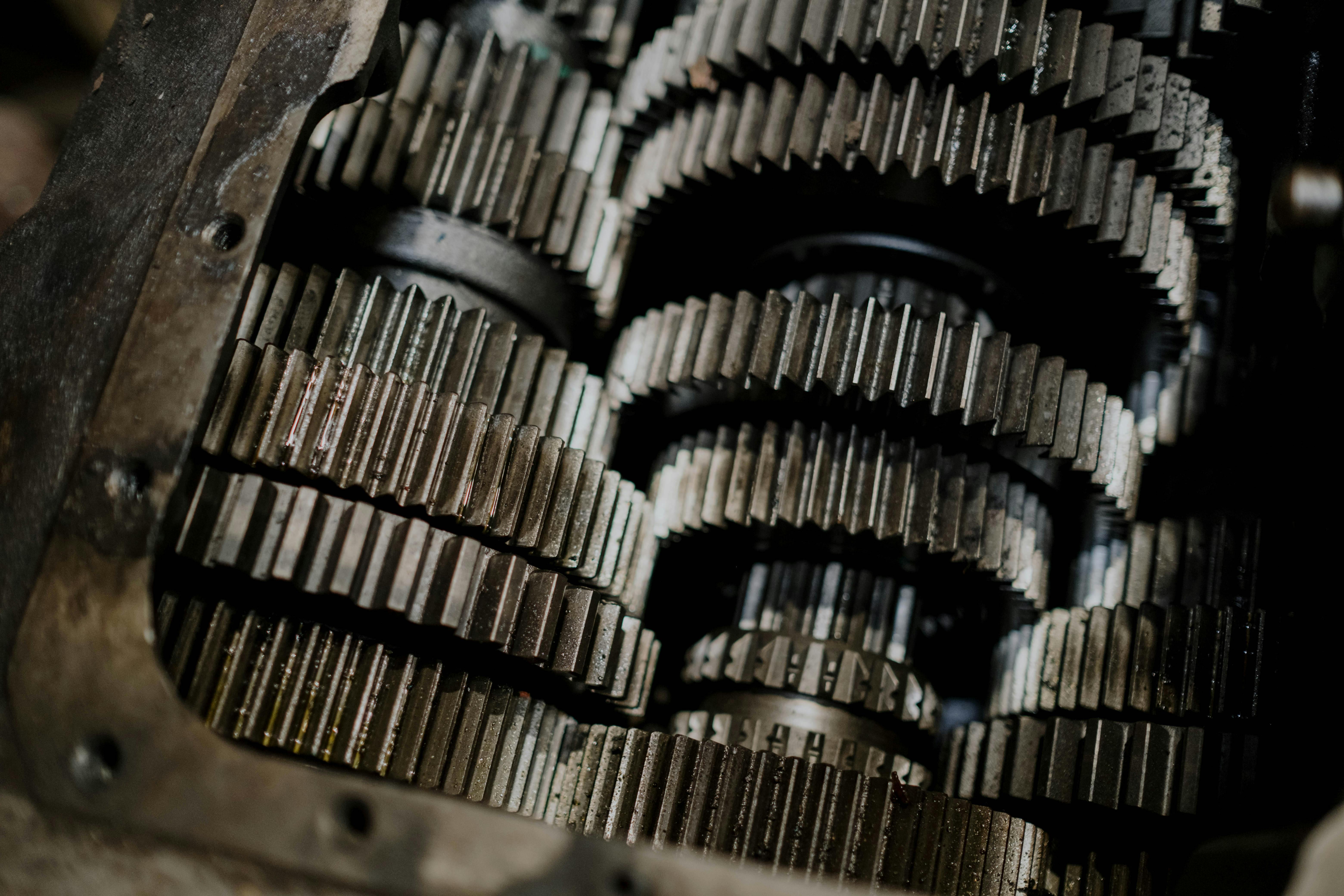

Warehouse automation can help to extend the life of a facility, reduce touches and handling or improve efficiency. Done correctly it can provide a step change in productivity enhancements and justify the substantial upfront investment. Like any capital project however, it is important to get the upfront thinking right to enable the necessary approval steps as well as the selection of appropriate automation partner and timely realisation of the intended benefits.

If you have not previously sat down to comprehensively evaluate how to use automation to improve the capacity, throughput or efficiency of your facility, then this can be a challenging process and if done poorly can result in wasted effort by all parties.

To assist you to successfully navigate this journey we have drawn up this series of insights, recognising that having the strategic thinking right up front is critical to both internal and external engagement. Having performed this for a number of clients, Siecap brings an unmatched level of rigour, but also a straightforward and collaborative approach to vendor engagement that not only facilitates better solutions, but also avoids unnecessary expense and disengagement by vendors.

What problem are you trying to solve?

- Start at the macro level, but back this with a strong understanding of your key drivers behind seeking an automated solution. Is it to facilitate growth, restructure the competitive landscape, reduce costs, reduce OH&S issues, improve stock security, respond to competition, or maximise space?

- Some key metric or triggers that you can consider as reasons for embarking upon the automation journey could be:

- Capacity of facility exceeded or imminently maxed (storage slots >85%, cubic capacity >24-27%, outside storage expanding)

- Labour costs increasing exponentially or out of control

- Productivity dropping with the addition of each FTE

- Customer service levels impeding growth (DIFOT, fulfillment errors, customer satisfaction, etc.)

- Competition has increased – competitors are fulfilling faster, more efficiently, fewer errors – leading to loss of growth or market share

- Increasing work cover premiums that are eventuating from outdated manual handling practices

Where is automation most likely to assist?

- Depending on where your biggest bottlenecks are occurring, the answer might lie in optimising the putaway and retrieval process, storage cube, storage security order fulfillment, packaging automation, or even order confirmation of high value SKUs (i.e. for claims reductions).

- It will certainly aid in achieving your standard key metrics.

Working with automation Vendors

Siecap have found that when that whilst directly engaging with vendors can assist you to hone your initial thinking it can lead to unforeseen issues. This manifests itself in two ways, an early buy into the wrong solution that closes the mind to other solutions or vendor / client capture. Both are easy traps to fall into. Hence a strictly agnostic approach coupled with extensive Vendor pre qualification is essential as is actively managing the competitive tension between ‘viable’ options. Remember the Vendors will invest significantly in any viable solution so it is in your interests to be seen as a reasonably successful proposition. Always approaching vendors in an open and collaborative manner will drive the optimal outcome for all parties. We frame the journey to do so in this manner.

1) Pre-Qualification – Vendor Engagement for Solution Development:

- Desktop research can help you pre-scope your desired assistance (including trade shows and the like), but at some point, you will need to reach out to perform pre-qualification, which may include a combination of phone, face to face, and site visits.

- In the early stages, your goals and those of the vendors are not necessarily aligned – you want to explore the market; they want to sell their solution. But they also want to avoid wasting time, resources, and money (typical RFx responses can cost vendors up to $100,000) when there is a lack of clarity, authority, need or ability implement, or if they perceive there is too much competition.

- The best way to combat this is to minimise waste in both your and their process by having a clear description of the project goals and drivers. Vendors will be more likely to engage the more you can share about what you are trying to solve and why it is important for your business (subject to NDA).

- A written brief including sharing of your business drivers and goals, desired metrics improvements, and time horizon, can be helpful in the pre-qualification stage to shortcut the discovery process on both sides and reduce unnecessary expense.

- Open collaboration (and feedback when the exercise has been completed) also helps vendors buy-in and propensity to cooperate.

2) Vendor Engagement for Partner selection:

- Building from the pre-qualification or request for information stage, it is critical to demonstrate your clarity, authority, and need – and ability to implement.

- We have found during the RFI process that the number of participants (through a combination of capability and selection) typically reduces to a manageable level where price, quality and implementation capability can then be judged via a tender process.

- Apply rigour in driving a consistent and thorough tender process is appreciated by respondents as they derive comfort in knowing they will be judged fairly.

- Tender process watchouts include:

- Creation of a thorough but clear tender document that is agnostic and avoids using collateral copied from a vendor. They quickly recognize if the sought specification aligns with another party’s solution

- Clarity on judgement criteria – both qualitative (references, implementation capability, project management, safety, compliance with regulations including ESG etc.,) and quantitative (cost, quality, applicability to the desired solution, timing etc.) is critical

- Who will perform the scoring and will it be impartial and rigorous?

- How will tenderers be engaged throughout the process and what feedback can be expected? What is that timeline?

- Form of desired contract, and when / how will tenderers’ legal be engaged?

3) Sign-off and program kick-off approach.

Well, that’s an article for another day!

Having successfully completed a number of projects focused on improving performance through the deployment of automation and intralogistics Siecap have been able to achieve tangible savings in headcount, efficiency, and/or capacity utilisation. Our rigorous, stepwise process can help you to avoid costly investment upfront in determining the solution and assist in finding the best partner for your unique situation and business requirements. Our industry leading approach ensures that when we take your brief to market it will treated as a priority by the solution providers. If you need consultative assistance in navigating your automation solutions, reach out to Siecap today at https://siecap.com.au/contact-us/.